Vastu Shastra is a science that deals with the construction and architecture. . It helps in maintaining a positive flow of energy in the constructed area and brings good luck and prosperity in commercial/office space.

where reasons and logic of science are used. Rules of Vastu Shashtra are observed by balancing the five elements of environment – ‘Panchabhutas’ (Water, Fire, Earth, Air, and Space). These rules define the directions and state what to place where and what should be avoided for the growth and prosperity of business.

It is important to build an office /Commercial as per the guidelines of Vastu. If you are planning to purchase or renovate a commercial space for your business, here are few tips which you should keep in mind for help in selecting the best Plot as per vastu directions & shape, layout, space arrangement, principles of design, entrance, Lockers, furniture etc.

Plot Shape & Direction– Plot should be Rectangular & Shermukhi plots. A rectangular plot of side ratios between 1:1 to 1:2 are best suited. but if it is not as per Vastu guideline, then the irregularity can be treated with various Vastu remedies.

According to the Vastu Shastra, the office/Commercial should always be North.

It is believed that North direction brings a lot of positivity and good fortune for business and is considered as an auspicious direction for all office space.

Entrance – An office/commercial should be in the North, North-East or North-West facing direction. These directions are considered to bring good fortune and positivity for business & the most auspicious directions for office spaces as well as commercial space. It makes employees feel fresh and very productive.

North Direction ( Kuber (the lord of wealth) direction), thus it profits you in financial terms as well.

East Direction – East direction the direction of a Service industry related office. East is a sunrise direction and it gives great growth to the work.

Reception /Welcome Area –

First impression on the visitors. The reception area should be very relaxing and one that gives positive vibes.

Welcome room should be located in the East Direction or the North-East Corner of the Plot/space. It is advisable to put a photo or idol of God in the reception area, and the Reception desk should be placed facing North-east direction. Decorating flowers and offering sweets in any way creates a positive aura and good relationship value with the visitors.

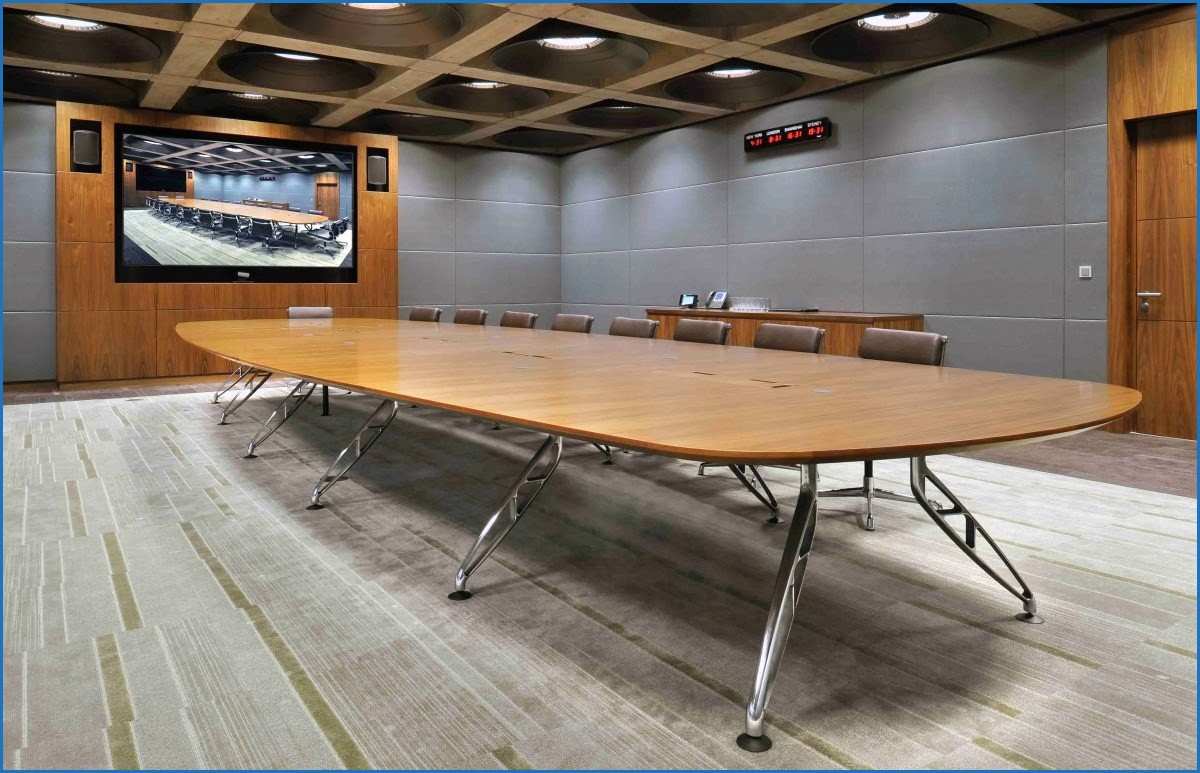

Conference Room – should be placed in the north-west direction. These zones can spur on projects, bring you good and reliable clients and ensure that sales and dispatch go well. For gaining useful connections, keep the North-West zone healthy. This will generate support and help from investors and lenders.

Finance department should be in the north and east zone and employees dealing with bank and cash transaction should sit facing east and north direction. All the financial records should be kept in central north or southwest of the cabinet.

Business Head – Business head should occupy a cabin in the western part of the office & facing towards East or North direction. . Also, make sure the temple or pictures of any Idol or God must not be placed at the back side of the owner’s seat.

Seating Arrangement – The seating arrangement in the office must be planned according to Vastu tips for office. For the Manager, Director and Executives of the office, the seating arrangement must be in the Southwest, South or West zone of the office as per commercial Vastu. The seating arrangement must be facing towards North or East while working in the office. Working while facing towards North or East direction increases the productivity of the employee. Plot Shape & Direction– Plot should be Rectangular & Shermukhi plots. A rectangular plot of side ratios between 1:1 to 1:2 are best suited. but if it is not as per Vastu guideline, then the irregularity can be treated with various Vastu remedies. According to the Vastu Shastra, the office/Commercial should always be North. It is believed that North direction brings a lot of positivity and good fortune for business and is considered as an auspicious direction for all office space.

Storage Rooms – should be in the south west. Waste material, too, can be stored in this direction.

Washroom – Washroom should be constructed in the West or North-West direction. Also, make sure the washroom is not in North-East, South-East or East direction.

Pantry – Pantry is very important in an office. Pantry should be located in the South-East direction; it is known to be the ideal direction & never construct a pantry in North direction.

One of the most important things is one should keep in mind while eating in office is that there should be a separate place for eating. It should not be painted in pink or red color.

Staircase – Best direction for Staircase in South or South-West. Make sure you dont construct one in the center of the office as it may lead to financial loses to the owner. And staircases must be painted in subtle light colors.

Colors – As per Vastu for Office/Commercial the décor and colors of the office should be bright and vibrant. Bright colors are known to spread positivity in each corner and it reflects light to all the directions.Using colors like blue, white and grey makes the aura cheerful. White, creams and tone of yellows can be used for Southeast, East, Northeast and Northwest walls.