The process of drying timer(removing moisture or sap, Present in a freshly felled tree, under more or less controlled conditions timber is called Seasoning of Timber.

Seasoning is the first step in the efficient utilization of timber.Tree contain a large quantity of moisture roughly From 100% to 200%, based on dry weight of wood.A well seasoned piece of wood may contain about 10% to 12 % moisture.

Purpose Of Seasoning of Timber :

To minimize the tendency to shrink, warp & split. To reduce the weight for transport purposes , Handling and thereby reduction in cost. To increase strength, durability and electrical resistance. To improve the wood working qualities in timber including gluing, Painting and polishing. To make it capable to a certain degree for protection from attack by insects and fungus.To make it fit for effective preservation treatment, otherwise the protective coat will close the outside pores and induce decay on the timber member.

Classification of Seasoning of Timber :

A)Prevention of drying of log:

The drying of the log should be induced by storing Them under water , which is incorrectly known as water seasoning.

b) End coating for preventing Splitting in Wood :

This can be prevented or minimized by coating the ends of logs and thick sections of all timbers with some kind of moisture proof substance , upto a distance of 80mm from the ends.

Some of the effective composition for end coating are given below :

1)Thick coat tar or bituminous paint.

2)Rousin and Lamp Black melted, mixed & applied hot.

3)Hardened Gloss Oil.

4) Paraffin Wax.

5) Molasses and lime (3:1).

Methods of Seasoning of Timber :

1)Air Reasoning or Natural Seasoning :

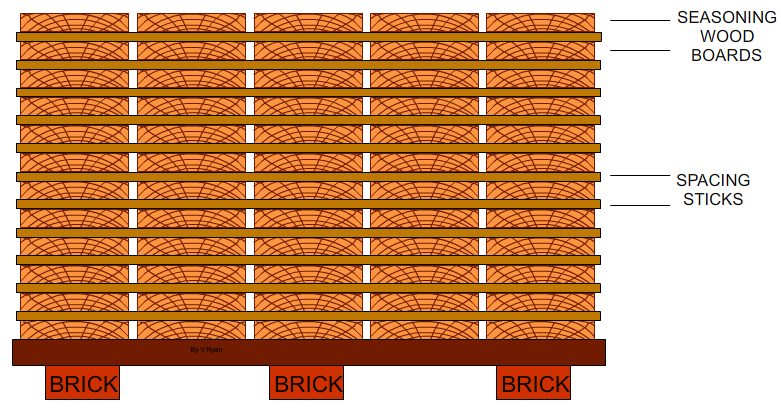

Provide free circulation of air so as to allow moisture to evaporate.This method consists in stacking the sawn timber in a dry place, should be made 300 to 450mm above ground level.

Long beam of strong timber, having cross section 100x 100mm, should be placed above the floor to serve as frame work for the stacking of timber.Air Seasoning is a slow process. Time Period depend Upon the size & type of timber, and season variations of climate.

a)Railway Sleepers :

The one and nine method is suitable for moderately heavy timber. The close crib method gives slower seasoning as it reduces the air circulation.This is recommended for stacking sleepers of refractory timber hot & dry localities. Containing about 100 sleepers

but center to center distance of crossers shall not exceed 1.5m.

B) Poles :

Poles should be stacked either in closed heaps or with crossers.The center to center distance of crossers should not exceed 3m.

“Open Crip Method “ in which case, the alternative layers of poles are at right angle to each other ,leaving a space more than 8cm between adjacent pole in the layer.

The convenient height is kept 3m. The center to center distance is kept 1.5m.

C) Bamboos :

These should be stacked in close heaps on foundation to any convenient height.

D) Scantlings and Squares:

Stacked should be Crossers 50mm x40mm in cross section, which are kept 2.5 to 3m apart.The height of stack may be kept upto 3m.

E) Planks :

Stacking of planks should be thickness And cross section 40x25mm for planks upto 50mm Thickness. The center to center distance of crossers in each layer should be 60cm for planks upto 50mm thickness.

Advantage :

1)Simple & Economical method. ● 2)It does not require much skill and attention in the process of seasoning.

3)Slow Process, the chance of seasoning defects in the timber are comparatively less.

Disadvantage :

1)Slow Process.

2)Large Space required for stacking timber.

3)More Capital investment is required which is otherwise blocked till the seasoning is complete.

4)The moisture contents cannot be reduced less than 15 to 18%. So timber ,seasoned by this method cannot used on certain jobs for which the moisture contents required is less.

5) The timber can easily attacked by insects and fungi due to long period of seasoning even under favorable conditions.

Klin or Artificial Seasoning :

Seasoning of timber in a Klin. It is a quick method of seasoning. The moisture

content by this method can be reduced to the extent of 8 to 12 % and timber can be used in a short time and according to the climate conditions of the locality.

Construction of klin :

It is usually a masonry chamber equipped with arrangement for heating , humidifying and circulating air in the klin.

Construction of klin :

Steam is generally used for heating & humidifying the air in modern klins through furnace gases are also used for supplying heat.It is also provided with propeller fans inside the chamber for rapid circulations of air.

Method :

The stack of timber is made as for air seasoning and the trolley containing stacked wood is driven inside kiln and the doors are closed tightly .

A boiler for heating and power for driving the fans are also used steam is injected through the steam Pipes in the chamber while the heating pipes are kept At low temperature.Full Humidity is maintained by the steam and evaporation from the surface of the timber members is prevented in spite of the heat which gradually reaches inside the timber members.

This process is also known as desiccating.

Proper circulation of hot air is maintained by driving the fans.

Started at a comparatively low temperature & higher Humidity. Conditions Gradually when temperature of air inside the kiln is fairly high and humidity is low or reduced.

Special instrument such as moisture meter etc. are used for testing some pieces of wood periodically to check the per moisture content.The period of kiln seasoning is also variable Accordingly To thickness and species of timber (4 to30days for 25mm thick planks).

Advantage :

1)Shortest time under controlled process. ● 2)The wood can be used immediately as and when required.

3)It renders the timber less liable to shrinkage.

4) It renders the timber les liable to be attacked by insects and fungi.

5) Moisture content reduce as per requirement.

Disadvantage :

1)It is a costlier method through space required is less.

2) Skilled labour is required.

3)Being a quick process of drying, a continuous Attention and watch is required, otherwise the Timber Is liable to seasoning defects such as end splits, Surface cracks, warping , internal cracks etc.